When Fabricon Design Ltd, design-led steel fabrication company, replaced its existing compressor installation with an Atlas Copco unit to sustain the air supply of its state-of-the-art CNC machining operation, it also gained the benefit of annual energy savings in the region of 51%.

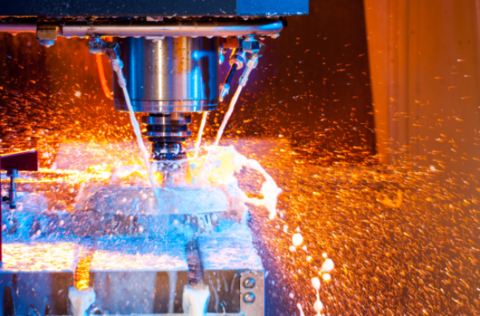

In its manufacturing role, the company machines tens of thousands of components on its 4-axis CNC centres each month, products destined for a wide variety of industry sectors and projects. The components can be as varied as metal fittings for stairlift equipment assembly, corner fixings for airport lighting systems, or essential aluminum parts for architectural fenestration systems.

To maintain this versatile output, Fabricon Design operates an investment strategy of continually upgrading to the latest developments in CNC milling machines. But, to fully exploit equipment capability, a reliable and adequate supply of compressed air must always be available as an integral part of the machines’ operation. Compressed air is required to operate the clamps and valves on the CNC machines and to control equipment temperature during dry cutting procedures.

This air requirement became even more critical when new production equipment was installed to replace the existing old, fixed-speed 11kW compressor because it didn’t have sufficient capacity to meet the demands from the new CNC machinery. Fabricon Design studied the compressor market, and invited Atlas Copco to come to the site, look at existing installation, monitor the system’s performance and report back with their recommendations.

A week-long iiTrak study of the regular compressed air usage pattern revealed the need for the existing compressor’s replacement and its relegation to standby duty. Calculations indicated long term savings with a 5-year payback from an upgrade plan recommending a new compressed air system. The installation would include an Atlas Copco GA15 VSD+FF rotary screw compressor with integral refrigerant dryer, together with a 900 litre-air receiver, quality air and condensate treatment ancillaries. It also advised a modification to the distribution pipework system to form a complete ring main, connecting two manufacturing areas with new AirNet pipework, in order to improve air pressure and flow throughout the workplace.

The full-feature Atlas Copco GA15 VSD+ compressor, delivering between 7 and 41.8 ls of quality air at 7 bar, is designed with innovative features to increase efficiency, cut energy consumption, lower noise levels, and reduce operating costs. The Atlas Copco compressor will save the company approximately 51% of its energy consumption, a figure which equates to £2479 per annum based on 10p/kWh for the electricity supply. The compressor now installed is factory fitted with Atlas Copco’s SmartLink − a remote data monitoring programme for compressors, to increase maintenance and service efficiency. For added peace of mind, the Fabricon Design installation is also protected by a Total Responsibility full-service maintenance contract with Atlas Copco.

The efficiency of the upgrade project operation has earned praise from Fabricon Design founder, Mark Bushdyhan.